Facts, Care & Maintenance

Granite & Natural Stone

Granite and natural stone bring natural beauty and character into any space. Here you’ll find helpful facts about these materials, along with easy care and maintenance guidance to protect your investment and enjoy it for a lifetime.

granite

Myths & Facts

Granite Stains Easily

Granite is resistant to stains. Generally, any liquid spilled on a granite top, if wiped up within a few minutes, will not stain. However, even water can soak into a granite countertop and leave a dark colored spot. This will evaporate out. Liquids that do not evaporate, such as oils, will cause stains if left to soak into the stone.

Granite Stains Permanently

Most stains in granite can be removed. Even oil stains can usually be removed using a poultice kit that will draw out the oil from the stone.

Granite Requires a Lot of Maintenance

Routine cleaning with mild soap and water is all that is generally required. We recommend a simple water bead test each year. Dropping a few drops of water on to the granite, the water should bead up similar to after you have waxed your car. If it does, your sealer is good for another year. If not, it is time to reseal. A reapplication of penetrating sealer is done professionally and is usually completed in under an hour. Our trained staff offers this service. Call out office in order to schedule an appointment..

Heat Damages Granite

Granite is heat resistant and can withstand the heat of hot pots and pans. However, we still recommend you protect your investment by continuing to use hot pads. The heat will not harm the stone, it can scorch the sealer. Many species of stone have natural fissures and these can open up if a significant amount of heat is applied to the cold stone. Stone is naturally cold. Therefore, pyrex or glass dishes that come out of the oven, microwave, or dishwasher hot, might crack when placed on the granite surface. This is a reaction known as Thermal Shock, caused by extreme differences in temperature. It is always best to use a hot pad.

Granite is Porous and Harbors Bacteria

Bacteria are found everywhere. If it is on a granite surface, it would also be found on a laminate, solid surface, or quartz top. Using an antibacterial soap with water to wash your granite countertop is the best preventive measure.

You Can Cut Directly on Granite

You can, but it’s not recommended. Regular steel knives are no match for the hardness of granite and your knives will dull.

choosing

Natural Stone

Natural Stone: Your Best Choice for Lasting Beauty

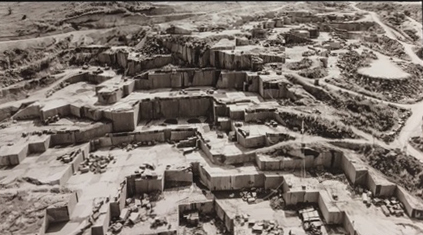

Natural stone has been the premium building material of choice since the beginning of time. Quarried from rock beds formed over millions of years, natural stone used in residential and commercial settings comes from all parts of the world.

Natural stone is quarried in the form of huge blocks, some weighing up to 20 tons. These blocks are cut into slabs generally 3/4” or 1-1/4” thick and the desired finish is applied. The slabs are then carefully crated and shipped to fabricators worldwide who process them into the final product.

Whether you’re building a new home or remodeling, natural stone offers you unparalleled beauty, permanence, and uniqueness– and adds true value to your home. Because stone is natural, not a manufactured product, no two pieces are exactly alike, which means each finished countertop, wall, floor, mantle, or sill is distinctive. And unlike synthetic imitations, natural stone can be three-dimensional and used as columns, statuary, balustrades, doorjambs, and even furniture pieces. When used in exterior applications, natural stone has also proven superior to manufactured or engineered products in withstanding the effects of nature.

Get to Know Your Stone

The first step in proper stone care and maintenance is to understand your stone’s geological classification and composition. This information will help you to identify what cleaning products to use and how to best care for your natural stone.

Natural stone is categorized into three basic geological classifications by their respective formation processes: sedimentary, metamorphic and igneous. Additionally, stones in each category can be either calcareous or siliceous.

Calcareous stone is composed mainly of calcium carbonate, a chemical compound commonly found in natural stone, shells, and pearls. Calcium carbonate is sensitive to acidic solutions so mild, non-acidic cleaners are recommended.

Siliceous stone, as the term implies, is one composed primarily or silicates, such as quartz, feldspar, mica, etc. As such, a siliceous stone is generally resistant to most acids found in kitchen settings, although acidic cleaners are still not recommended, as these stones may contain trace levels of minerals that are acid sensitive.

The following chart will be a helpful guide:

| Sedimentary | Metamorphic | Igneous | |

| Calcerous |

Limestone Travertine Onyx |

Marble Serpentine |

|

| Siliceous | Sandstone |

Slate Quartzite Soapstone |

Granite |

Colors & Appearance

Natural stone is quarried throughout the world in a variety of colors with varying mineral compositions. If you have stone in your home and do not know the type, you may want to consult with a stone professional. In most cases, the type of natural stone can be identified by visible particles at the surface of the stone.

Finishes

There are several finished (for example: polished, honed, leathered, antiqued, and others) available for natural stone and new finishes appear in the market regularly to keep pace with consumer demand. The type of finish will not impact the type of cleaning product used.

Usage

The harder the stone, the more it resists abrasion. Granites are typically the hardest of all stone types. Using a softer stone simply requires the homeowner to use gentler cleansers and more frequent dusting to prevent scratching. Consult with your contractor about the stone you have selected and its intended use.

Types of Natural Stone

Marble

Ideal for: Foyers, Bathrooms, Floors, and Fireplaces

Marble adds a sophisticated element to your home. Its wonderful appearance, superior engineering characteristics, and ease of maintenance make it a popular choice for countertops, floors, foyers, fireplaces, furniture, showers, thresholds, tub decks, vanities, walls, and windowsills.

Another option for marble-loving homeowners is using serpentine for kitchen counters. Sometimes called the “green” marble, serpentine is not a true marble, but offers a marble-like look. And, because it is magnesium-silicate based, it is not sensitive to citric acid and other kitchen spills.

Marble should be cared for as you would a fine wood finish. Using coasters on table tops and cleaning up spills immediately will preserve marble’s natural beauty and elegance.

Granite

Ideal for: Kitchen Countertops, Floors, and other Heavily Used Surfaces

Granite, quarried from the mountains of Brazil, the U.S., India, and dozens of other countries, is one of the most popular natural stones on the market.

Available in a striking array of colors, granite’s durability and longevity make it ideal for kitchen countertops and other heavily used surfaces, including table tops and floors.

While some synthetic surfaces scratch easily and melt under hot cookware, granite resists heat. Granite offers an impenetrable surface from which bacteria can easily be cleaned and it is typically not affected by citric acid, coffee, tea, alcohol, or wine. It is also nearly impossible to scratch, and with proper cleaning, will not stain under normal use (ask your professional contractor about “impregnating” sealants available to further improve resistance to staining).

A leading consumer magazine recently compared granite with engineered stone, ceramic tile, laminate, butcher block, and other manufactured surfaces. Granite received the highest overall performance rating as a kitchen countertop material.

Because of its exceptional strength, granite is well suited for exterior applications such as cladding, paving, and curbing.

Travertine, Limestone, Soapstone, and Slate

Ideal for: enhancements inside or outside your home

Travertine is a type of limestone and one of the most popular natural stones for interior and exterior wall cladding, interior floor and exterior paving, statuary, and curbing.

Limestone is widely used building stone with colors typically light gray, tan or buff. A distinguishing characteristic of many limestones is the presence of fossils that are frequently visible in the stone surface. Popular applications include countertops, flooring, interior and exterior wall cladding, and exterior paving.

Soapstone may come in a wide range of colors and generally feel smooth to the touch. Due to its high resistance to chemicals and because of its ability to absorb and distribute heat, it is an ideal material for countertops, fireplaces surrounds, and wood stoves, as well as bathroom vanities and stair treads.

Sandstones vary widely in color due to different minerals and clays found in the stone. Sandstone is typically light gray to yellow or red. Bluestone and brownstone are well known varieties of this quartz-based stone group. Sandstone is frequently used for fireplace facings, chimneys, garden walls, patio benches, and at poolsides.

Slate is dark green, black, gray, dark red or multi-colored. It is most commonly used as a flooring material and for roof tiles and is often distinguished by its distinct cleft texture. Other slate applications include kitchen countertops, fireplace facings, table tops, and roofing.

Download Guide

Allowable Repair

Repair of stone countertops must be performed by competent, experienced artisans to achieve the desired results. Repair of the stone is permitted when the repaired region is not in a structurally significant area of the countertop, and when it can be accomplished skillfully so that the repair is consistent in color and texture with unrepairable regions of the slab.

Fissures

Fissures occur naturally in many stone types. A fissure is defined by American Geological Institute as, “An extensive crack, break, or fracture in the rock, which may contain mineral-bearing material.” The term “fissure” is used commercially in the stone industry to describe a visible separation along intercrystalline boundaries. This separation may start and stop within the field of the stone or extend through an edge. A fissure differs from a crack in that it is a naturally occurring feature in the stone that may be found in other areas of the same slab or other slabs of the same material.

Cracks

Cracks occur in stones as a result of man-made mechanically induced stressed during handling, fabrication, transport, or installation. When cracks are detected in slab material prior to fabrication, the best method is to simply avoid including them in the product through culling during the layout process. In stones with lesser soundness properties, this option may not be practical, or possible. When working with such stones it is common practice to repair cracks by cementing them together with epoxy or polyester resin, either with or without dowel reinforcement. Cracks that occur as a result of handling-induced stresses are more difficult to repair, as they commonly include chipping in addition to the crack. Repair is frequently performed by injection of a penetrating resin adhesive, which may be dyed to match the stone, and then rebuffing the area after curing of the resin. In many cases, the entire stone must be repolished to make the repair unnoticeable. If the repair is attempted but unsuccessful, the stone is to be replaced with a new piece.

Chips

Chips can occur in stones either as a result of sawing operations or handling and restraint devices. Particularly in the igneous stone varieties, the exiting portion of the diamond blade will create many small chips. A small chamfer, called an “arris,” of approximately 1/16” x 1/16” (1.5 x 1.5mm) can be used to eliminate most of these small chips. The use of an arris will make the seam appear wider than its actual dimension when filled. Larger chips may be repaired with epoxy or polyester resin if the completed repair is consistent in color and texture with unrepairable areas of the slab. In many materials, the resin used in the repair will appear more natural if it is not dyed.

Pitting

Pitting of the countertop surface, particularly in granite material, is a commonly seen characteristic on natural stone. Granites are made up of several different minerals, each mineral having a different hardness. Granites contain quartz, feldspars, biotite, amphibole, ferrous titanium oxides, and other mineral combinations. On the Mohs Scale, diamonds are the hardest mineral, with a rating of 10. Quartz and feldspar have a hardness of 6.5 to 7 and are very durable. Biotite (small, black minerals throughout the slab) on the other hand is very soft (2.5) and flakes easily. All true granites have biotite in their composition. Because biotite is relatively soft and flaky, the first few layers are often removed during the polishing process, causing pits throughout the slab. Some granites have more biotite throughout their composition than others. The higher the biotite content of the stone, the more pits it will have. Most polished igneous rocks will have varying degrees of pits, depending on the amount of biotite, muscovite, and phlogopite in their composition.

The pits do not make granite less durable or otherwise inferior, and do not in themselves qualify the slab for replacement. Pits are common in all granites and should be expected when dealing with a natural, polished stone containing several types of minerals with different hardnesses. It is usually best to not attempt repair of puts, as most repair techniques will not cosmetically improve the countertop.

Maintenance

Application of Sealers. The application of a topical sealer or impregnator is a common step in decreasing the vulnerability of the stone to stains.

Impregnators will penetrate the stone and cure a few millimeters below the surface, residing in the intercrystalline boundary areas and pores of the stone. The products do not actually “seal” the stone, and are more correctly referred to as a repellent rather than a sealer. As such, they are formulated to prevent transmission of liquids, while allowing transmission of vapor. Since they reside below the actual surface of the stone, the change to the appearance of the stone surface is minimal. Impregnators will be either hydrophobic, in that they repel water-based fluids. The manufacturer of the impregnator product will recommend a reapplication interval.

General Precautions. When any surface protection product is used, care must be taken to read and follow the manufacturer’s written instructions accurately. This will provide the greatest benefit from the application and will guarantee safe handling of the product.

Care and cleaning practices of the stone countertop are to be thoroughly discussed with the client upon completion and installation. Refer to the MIA brochure Care & Cleaning for Natural Stone Surfaces for more information.

Outdoor Kitchens

General Precautions. An increasingly popular area for stone countertops is in outdoor kitchens. The installation of natural stone countertops in these areas creates additional challenges from the installation of the indoor countertops for suppliers and installers. Due to extreme temperature changes, UV exposure and varying moisture levels, typical installation methods along with certain materials cannot be used.

Customer Communication. In addition to the suggestions stated earlier, customers should be made aware that due to the use of resins in the finishing process of natural stone, they will most likely experience some fading in their countertops. Nearly all resins used in the fabrication process are subject to color change and surface degradation when exposed to UV light.

Materials. It is recommended that only sound stones with minimal geological flaws or voids be used for these areas. Stones that contain these voids or fissures may experience the growth of mold and mildew, the loosening of filler materials and in some cases, cracking and separating due to extreme temperature changes.

Subtops. All areas that are to receive stone countertops should have a sub top or axillary frame made of cement board or mortar bed. The subtop or auxiliary framing should be rated for exterior use.

Adhesives. All adhesives to be used must be suitable for exterior installations. Since silicone is frequently used on outdoor kitchens, care must be taken to insure that staining does not result from plasticizer migration of some silicone products. Polyester adhesives should be avoided in an exterior environment.

Seam Filler Materials. All materials that are to be used for seam filler must be suitable for exterior installations and allow for some movement. Joint widths between two stone units should be nominal 1/16” + 1/16.” Undermount sinks can be anchored to the underside of the stone countertop or carried by a subtop or auxiliary frame. A subtop or auxiliary framing may be required and should be rated for exterior use.

Easy Care Tips

To get the longest life and preserve the beauty of your natural stone, follow these simple tips:

- Coasters: Use coasters under all glasses, particularly those containing alcohol or citrus juices.

- Trivets: While many stones can withstand heat, the use of trivets or mats is recommended.

- Dust Mopping: Dust mop interior floors frequently using a clean non-treated dry dust mop. Sand, dirt, and grit are abrasive and can damage natural stone.

- Mats/Rugs: Mats or area rugs inside and outside an entrance will help to minimize the sand, dirt and grit that may scratch the stone floor. Be sure that the underside of the mat or rug is a slip resistant surface.

- Vacuum Cleaners: If used, be sure the metal or plastic attachments or the wheels are not worn as they can scratch the surface of some stones.

- Spills: Blot the spill with a paper towel immediately. Don’t wipe the area, it will spread the spill. Flush the area with water and mild soap and rinse several times. Dry the area thoroughly with a soft cloth. Repeat as necessary.

Cleaning

Consult your stone supplier for cleaning product recommendations best suited for your natural stone.

- Clean stone surfaces with a neutral cleaner, stone soap, or a mild liquid dishwashing detergent and warm water.

- Similar to any item cleaned in your home, an excessive concentration of cleaner or soap may leave a film and cause streaks.

Follow manufacturer recommendations.

- Use a clean rag mop on floors and a soft cloth for other surfaces for best results.

- Rinse the surface thoroughly after washing with the soap solution and dry with a soft cloth.

- Change the rinse water frequently.

- In the bath or other wet areas, soap scum can be minimized by using a squeegee after each use. To remove soap scum, use a non-acidic soap scum remover or a solution of ammonia and water (about 1/2 cup ammonia to a gallon of water). Frequent or over-use of an ammonia solution may eventually dull the surface of some stone types.

- In outdoor pool, patio or hot tub areas, flush with clear water and use mild bleach solution to remove algae or moss.

Cleaning Products

- Many suppliers offer products used for stone cleaning.

- Products containing lemon, vinegar or other acids may dull or etch calcareous stones.

- Scouring powders or creams often contain abrasives that may scratch certain stones.

- Many commercially available rust removers (laundry rust stain removers, toilet bowl cleaners) contain trace levels of hydrofluoric acid (HF). This acid attacks silicates in addition to other minerals. All stones, including granite and quartzite, will be attacked if exposed to HF.

- Do not mix ammonia and bleach. This combination creates a toxic and lethal gas.

Sealing

Sealing is a common step taken on some stones as an extra precaution against staining. In fact, the sealing products used in the stone industry are “impregnators” which do not actually seal the stone, but more correctly act as a repellent rather than a sealer. Sealing does not make the stone stain proof: rather, it makes the stone more stain resistant.

When consulting with your stone supplier, you may find that many stones do not require sealing. However, applying an impregnating sealer is a common practice.

When considering sealing, remember that sealing the stone does not make it stain proof. It makes it more resistant to staining.

If a sealer is applied in a food preparation area, be sure that it is non-toxic and safe for use.

Consult with your supplier or sealing manufacturer specific to the type of sealer and frequency of use recommended.

Stain Identification Tips

Identifying the type of stain on the stone surface is the key to removing it. Stain can be oil based, organic, metallic, biological, ink based, paint based, or acid based. If you don’t know what caused the stain, consider likely staining agents that may have been present. Here are some questions to consider:

Where is the stain located?

Is it near a plant, food service area, or an area where cosmetics are used?

What color is it?

What is the shape or pattern?

What occurs in the area around the stain?

What type of stain is it?

The following sections describe the types of stains you may have to deal with and the appropriate household chemicals to use and how to prepare and apply a poultice to remove the stain.

Oil-Based

i.e. grease, plumbers’ putty, tar, cooking oil, milk, cosmetics

An oil-based stain will darken the stone and normally must be chemically dissolved so the source of the stain can be flushed or rinsed away. Clean gently with a soft, liquid cleanser with one of the following: household detergent, mineral spirits, acetone.

Organic

i.e. coffee, tea, wine, fruit, tobacco, paper, food, urine, leaves, bark, bird droppings

May cause a pinkish-brown stain and may disappear after the source of the stain has been removed. Outdoors, with the sources removed, sun and rain will generally bleach the stains. Indoors, clean with 12% hydrogen peroxide (hair bleaching strength) and a few drops of ammonia.

Metal

i.e. iron, rust, copper, bronze

Iron or rust stains are orange to brown in color and follow the shape of the staining object such as nails, bolts, screws, cans, flower pots, and metal furniture.

Copper and bronze stains appear as green or muddy brown and result from the action of moisture on nearby or embedded bronze, copper or brass items. Metal stains must be removed with a poultice. Consult a stone professional, or visit www.naturalstoneinstitute.org/consumers/poultices/. Deep-seated, rusty stains are extremely difficult to remove and the stone may be permanently stained.

Biological

i.e. algae, mildew, lichens, moss, fungi

Clean with diluted cleaning solution. Use a 1/2 cup of any of the following: ammonia, bleach, or hydrogen peroxide and a gallon of water. Reminder: do not mix bleach and ammonia.

Ink

i.e. magic marker, pen, ink

On light colored stones, clean with bleach or hydrogen peroxide. On dark colored stones, clean with lacquer thinner or acetone.

Paint

Small amounts can be removed with lacquer thinner scraped off carefully with a razor blade. Heavy paint coverage should be removed only with a commercial “heavy liquid” paint stripper available for hardware stores or paint centers. These strippers normally contain caustic soda or lye. Do not use acids or flame tools to strip paint from stone. Paint strippers can etch the surface of the stone; repolishing may be necessary. Follow the manufacturer’s directions for use of these products, and flush the area thoroughly with clean water. Protect yourself with rubber gloves and eye protection, and work in a well-ventilated area. Use only wood or plastic scrapers for removing the sludge and curdled paint. Normally, latex and acrylic paints will not cause staining. Oil-based paints, linseed oil, putty, caulks and sealants may cause oily stains. Refer to the section on oil-based stains.

Water Spots & Rings

i.e. surface accumulation of hard water

Buff with dry 0000 steel wool.

Fire & Smoke Damage

Older stones and smoke or fire-stained fireplaces may require a thorough cleaning. When the smoke is removed, there may also be come etching (due to carbonic and other acids in smoke). Commercially available “smoke removers” may save time and effort.

Etch Marks

caused by acids left on the surface of the stone

Some materials will etch the finish but not leave a stain. Others will both etch and stain. Contact your stone dealer or call a professional stone restorer for refinishing or repolishing etched areas.

Efflorescence

a white powder that may appear on the surface of the stone

This is caused by the deposition of mineral salts carried by water from below the surface of the stone. When the water evaporates, it leaves the powdery substance. If the installation is new, dust, mop or vacuum the powder.

You may have to do this several times as the stone dries out. Do not use water to remove the powder; it will only temporarily disappear. If the problem persists, contact your installer to help identify and remove the cause of the moisture.

Scratches & Nicks

Slight surface scratches may be buffed with dry 0000 steel wool. Deeper scratches and nicks in the surface of the stone should be repaired and repolished by a professional.

For More Information

For more information about using and caring for natural stone, please visit:

www.usenaturalstone.com

Ready for Your Transformation?

Take the next step in your journey with Gordon Creek Granite. Our team is ready to assist you in creating the space of your dreams. Whether you’re just starting or ready to finalize your design, we’re here to help. Contact us today to schedule your consultation and begin the exciting process of transforming your home with the timeless beauty of natural stone.